The Micro-Electromechanical Systems laboratory, located in EASC building room 1015 has been outfitted with:

Zeiss EVO-15 Scanning Microscope with Bruker Detector:

The instruments of the EVO combine high performance scanning electron microscopy with an intuitive, user-friendly experience. Within minutes will begin capturing stunning images. EVO excels at extracting the maximum data quality from uncoated and unaltered samples.Electron emission from a lanthanum hexaboride cathode, rather than a traditional tungsten hairpin filament, provides the reassurance that every extra bit of image quality is there when you need it.

Quality analysis / quality control

Failure analysis / metallography

Cleanliness inspection

Morphological and chemical analysis of particles.

Analysis of non-metallic inclusions

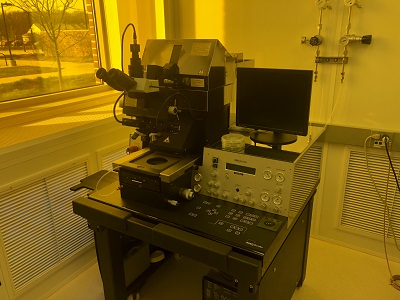

SÜSS MicroTec SE MA/BA6 Mask and Bond Aligner:

The high resolution optical and exposure systems of the MA/BA6 ensure valuable support for all areas of application. Even for MEMS applications with thick photo resists, high resolution and optimal edge illumination are assured. The special tooling comes to the fore even with sensitive III-V substrates and thinned or warped wafers.

Features like the accurate proximity calculations (e.g. for wedge error compensation) ensure smooth processing. Further support comes from the user-friendly process management and the easy loading and unloading of the device.

Mask aligner for the highest level of alignment precision.

Clear and stable pattern recognition even under poor contrast conditions.

Superior resolution as a result of diffraction-reducing optics.

Process stability through the use of micro lens optical systems.

WS-650-23 Spin Coater Process Controller:

The 650-series process controller utilizes a robust microprocessor and, with the use of its accompanying PC software (written in an object-oriented programming language), it achieves nearly unheard of flexibility both in process definition and use. This controller allows operator interaction in real-time during the process execution.

Elix Technology Inside Milliq Integral 15:

Milli-Q® Integral is a unique combination of optimized water purification and monitoring technologies. It allows, in a single device, both pure (Type 2) and ultrapure (Type 1) water to be produced directly from potable water. This all-in-one concept offers several benefits:

Provides users with complete control over all water purification steps and the final water quality.

Wafer Process System:

Title : Acid Wet Bench.

Model: WPS-400-FA-PVC-C

The Wafer Process Systems Inc. Model WPS-400-FA-PVC-C is a factory mutual approved noveon PVC-C vertical laminar. It’s a flow front access wet process system designed to process Si and GaAs wafers. All processed in class 10 environments.

Title: Solvent Wet Bench.

Model: WPS-400-FA-SS

The Wafer Process Systems Inc. Model WPS-400-FA-SS, Factory Mutual Approved Stainless Steel Solvent Wet Process System is designed to process Si and GaAs wafers.

Title: IPA Vapor Dryer.

Model: WPS-300-FA-SS

Wafer Process Systems, Inc.’s IPA Vapor Dryer provides enhanced drying performance for a variety of substrates and material surfaces. This proprietary drying process and its subsystems remove water, without leaving watermarks. The system efficiently creates the flexibility necessary to dry high aspect ratio / deep trench topography, half-pitch wafer spacing, and a wide variety of other applications.

Xetch® X4 Series System:

XeF2 (xenon difluoride) isotropic silicon etching is particularly well suited to MEMS applications. XeF2 vapor phase etching exhibits nearly infinite selectivity of silicon to photo-resist, silicon dioxide, silicon nitride and aluminum. Being a vapor phase etchant, XeF2 avoids many of the problems typically associated with wet processes.

Kurt J. Lesker ,Thin Film Deposition System:

The methods used to deposit thin films are split into: Physical Vapor Deposition (PVD) Chemical Vapor Deposition (CVD) depending on the underlying principles causing film deposition. A PVD method evaporates or sputters a material, producing a gaseous plume or beam that deposits a film on the substrate.

Heidelberg Instruments DWL 66+:

The DWL 66+ laser lithography system is an economical, high resolution pattern generator for low volume mask making and direct writing. The capabilities and flexibility of this system make it the ultimate lithographic research tool in Life Science, Advanced Packaging, MEMS, Micro-Optics and Semiconductor.