A University of Maryland Eastern Shore researcher and his colleagues at laboratories along the East Coast and as far away as Spain received national recognition by the U.S. Department of Agriculture’s Agricultural Research Service for their work aimed at controlling ammonia emissions in poultry houses.

Many areas in the country produce more manure nutrients than available cropland can assimilate. The removal and recovery of ammonia, therefore, is a desirable feature for new treatment technology for livestock effluents (liquid wastes that pour into natural bodies of water and subsequently the air). The nutrients instead could be exported off the farm, which could solve the problems of nitrogen surpluses in concentrated livestock production, serve as a substitute for commercial fertilizers and create new businesses.

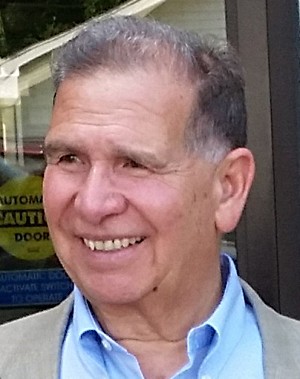

Dr. Fawzy Hashem, an associate professor in UMES’ Department of Agriculture, Food and Resource Sciences, was among the team members who received the 2021 Excellence in Technology Transfer National Award from the Federal Laboratory Consortium for Technology Transfer. According to the consortium’s notification letter, Hashem’s team was “one of a select number of recipients, an indication that your nomination was truly of the highest caliber.”

The annual award recognizes scientists from among the 300 laboratories supported by the Federal Laboratory Consortium “who have accomplished outstanding work in the process of transferring federally developed technology.” According to the agency, the shared technology can have profound impact on the nation’s economy and everyday life. Hashem and his colleagues will accept the award at a virtual ceremony on April 7 as part of the organization’s national meeting.

Their research was also selected last spring for a 2020 USDA Technology Transfer Award for the Southeast region. It focuses on the recovery of ammonia-nitrogen from waste using gas-permeable membranes. The process, Hashem said, includes the passive passage of ammonia through micro-porous hydrophobic membranes and subsequent concentration in a clear solution. The new technology’s application is the removal and recovery of nitrogen from liquid manures in storage tanks and from the air of poultry and animal barns.

“Using a wide variety of technology transfer mechanisms and activities covering the ammonia capture technology for both liquid and air applications, we found that 98 percent of the nitrogen can be recovered using the technology,” Hashem said. “Conservation and recovery of nitrogen from livestock production and wastes from industrial and municipal sources is vital for environmental and economic reasons.”

The team worked with industry to improve the technology with the goal of marketing a reliable and proven product with competitive advantages for commercialization. The researchers illustrated the technology to university and research center scientists during three on-farm demonstrations. They also presented webinars and training modules to the USDA’s Natural Resources Conservation Service and the Environmental Protection Agency. Their work was featured in high-impact scientific publications and numerous press articles.

Hashem’s team members included Drs. Matias Vanotti and Ariel Szogi from the USDA-ARS, Southeast Area; Dr. Patricia Millner from the USDA-ARS in Beltsville, Maryland; Dr. Michael Rothrock Jr., from the USDA-ARS; Gail Poulos, USDA-ARS, Office of Technology Transfer; Dr. Maria Garci-Gonzalez, USDA-ITACyL at the Agricultural Technology Institute in Spain; Dr. Patrick Dube at the Water Environment Federation; and Jeff Dawson at the Renewable Nutrients LLC in Southern Pines, North Carolina.

Photos above show the recovery of gaseous ammonia from the air in poultry houses using gas-permeable membrane technology at the University of Maryland Eastern Shore.

Left: UMES and USDA-ARS staff calibrate the ammonia recovery module. Right: Membrane manifolds placed close to the litter surface inside chicken barns are shown.