UMES’ pharmacy school fills a local need with 3D printer face shield parts

Thursday, May 7, 2020

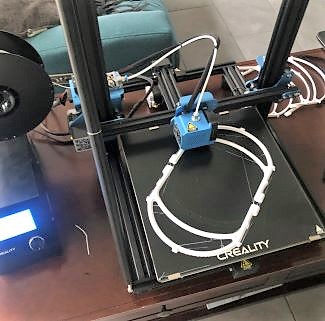

A 3D printer the University of Maryland Eastern Shore’s pharmacy school uses to manufacture nasal spray bottles for narcotic-overdose training is cranking out adjustable headbands for mounting plastic report covers with elastic straps to create face shields.

The first batch of 50 produced by Dr. Richard De Benedetto has been donated to Coastal Hospice, a Salisbury-based organization of some 190 people who provide specialized care for the gravely and terminally ill in supervised settings and at home.

De Benedetto said he was motivated professionally and personally to support front-line healthcare givers. His wife, Suzannah, is a spiritual consultant who counsels patients and works alongside hospice staffers.

“I thought maybe there was something a little extra I could possibly do to keep her and her colleagues safe,” he said.

De Benedetto teaches UMES pharmacy students about the dangers of opioid abuse and trains them on how to administer naloxone, an overdose antidote administered in spray form.

He did some online research and found a template he adapted to his 3D printer to create headbands to which a plastic shield and elastic can be affixed. The 8½-by-11 inch clear plastic is actually the same material used for covers of hard copy reports commonly used by commercial printers.

A single headband takes about two hours to make using the 3D printer.

Alane Capen, Coastal Hospice’s president, was unaware the donation was in the works when De Benedetto and faculty colleagues Rondall Allen and Sean Vasaitis showed up Thursday to make the presentation.

Capen called the donation “joyous. It affords us to be better prepared if this pandemic worsens in our community.

Vasaitis, an associate professor of pharmacology and U.S. Patent holder, got UMES involved when a distant relative reached out several weeks ago inquiring if the university might have interest in helping produce protective gear for hard-hit northern New Jersey, where COVID-19 cases were overwhelming healthcare workers. Before a modest supply of filament was exhausted, UMES aviation science instructor Chris Hartman voluntarily produced about 40 headband frames for shields that were sent to Vasaitis’ relative to help those most in need.

De Benedetto estimated each ready-to-wear face shield was produced with no more than a dollar’s worth of material. Each headband took about two hours to create.

Capens said the face shields wear out quickly because constantly sanitizing them eventually makes the plastic cloudy like headlights on old automobiles.

“There’s definitely a need,” she said. “I’m not sure we’ve experienced the worst of (the pandemic) yet.”

Bob Miller, Coastal Hospice’s business development director, said, “This (gesture) is what we’re about – paying it forward to help someone in need. UMES stepped up.”