Students design 3D zero-gravity payloads

Wednesday, October 31, 2018

UMES physics professor Kausik Das spent a week with the National Research Council of Canada in mid-October participating in suborbital flights to conduct experiments under zero-gravity conditions, including one developed by four University of Maryland Eastern Shore students.

Das worked alongside and observed astronauts and scientists who were testing potential modifications to body-sensors in space suits for the International Space Station.

To simulate outer space, Das flew aboard a custom-built Falcon 20 aircraft for a roller coaster-like ride – known as a “parabolic” flight, which he described as “an ‘out-of-the-world’ experience Literally!”

Das has been collaborating with space agencies since 2001, when he was a post-doctoral researcher at the University of California Santa Barbara and participated in a NASA-funded project on the behavior of fluids in reduced gravity.

Later, working at the University of Toronto as a research fellow and physics lecturer, he was involved in Canadian Space Agency research of “g-jitter” — science shorthand for time-dependent variations of the body force in orientation and magnitude in low-gravity environments.

“For this (October 2018) mission, one of my collaborators from the Massachusetts Institute of Technology and I proposed a zero-gravity experimental study through the (citizen-science astronautics) program known as Project PoSSUM,” said Das, who joined the UMES faculty in 2014.

Guiding current UMES undergraduates, he said, “we built a payload to test our solid-body rotation experiment in zero-gravity.”

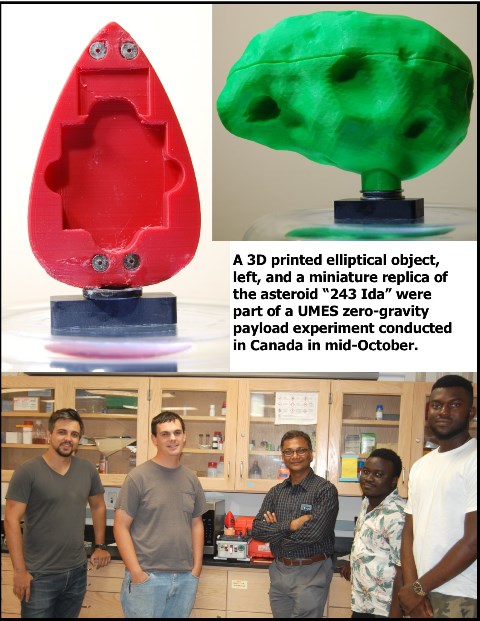

Nathan J. Bane, Justin E. Derickson, Ayobami O. Ogunmolasuyi and Jesudara Omidokun built “the whole experimental payload … from scratch. They designed it and 3D printed the parts, designed their own printed circuit board (and) their own circuit, wrote a customized code to run it, assembled it, tested it and trouble-shot it.”

“The goal was designing an experiment that could be conducted in a zero-gravity environment to exhibit and measure the rotational behavior of objects,” he said. UMES’ Solid Body Rotation Experiment “was designed to study, analyze and model the free-body rotation of objects in a near-weightless environment.”

“Measurements were captured by a small, battery-powered sensor … embedded in three rotational 3D-printed objects: a T-shape, an egg and an asteroid,” Das said.

The objective, he said, “was to benchmark experimental observations of the T-shaped and the oval objects, and study and compare data of the rotational modes of a 3D printed version of an asteroid known as ‘243 Ida’ with real astronomical data.”

* * *

Long term, Das said, the “goal is to model the behavior of these asteroids and understand the state of the universe, when they were created with the assumption that their rotational momentum is conserved from the time of their creation.”

UMES’ payload experiments “produced large amount of numerical and video data of different rotational modes of various shapes of solid bodies,” he said. “We are … extracting several terabytes of experimental video data for the purpose of post-processing and analysis.”

Das said “the payload worked as it was supposed to work, and it produced data. So we call it successful.”

He’s hopeful UMES will be invited to participate in 2019. He and the students will review the payload’s performance and look for ways to improve the design and maneuverability.

Das tells his students the space industry will need a large number of workers properly trained and capable of generating ideas for new innovative technologies.

Meanwhile, he came away from his first exposure to “zero-g” with an appreciation for those who able to focus on conditioning of the body, proper diet and having stress free mind to complete missions successfully.

“The experience can’t be described in words and is one-of-a-kind,” Das said. “I have started counting my days for the next year’s flight campaign.”